General Description of the Software Product

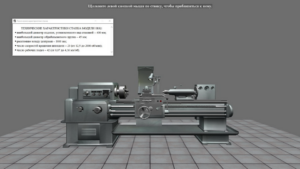

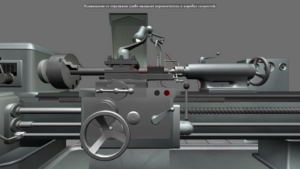

Software laboratory complex for the simulation of laboratory work on the main sections of the course of metal cutting technology for students of technical specialties.

List of virtual labs:

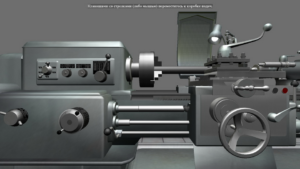

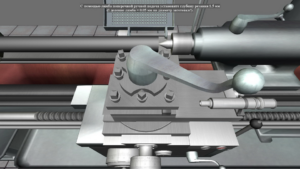

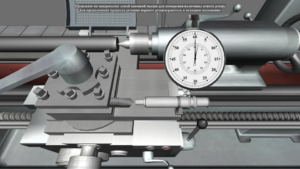

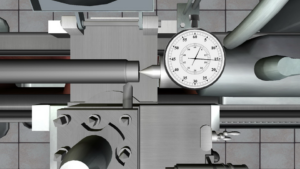

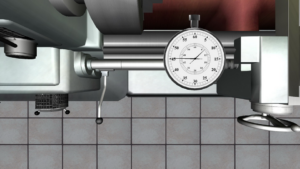

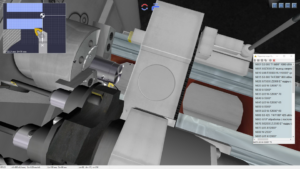

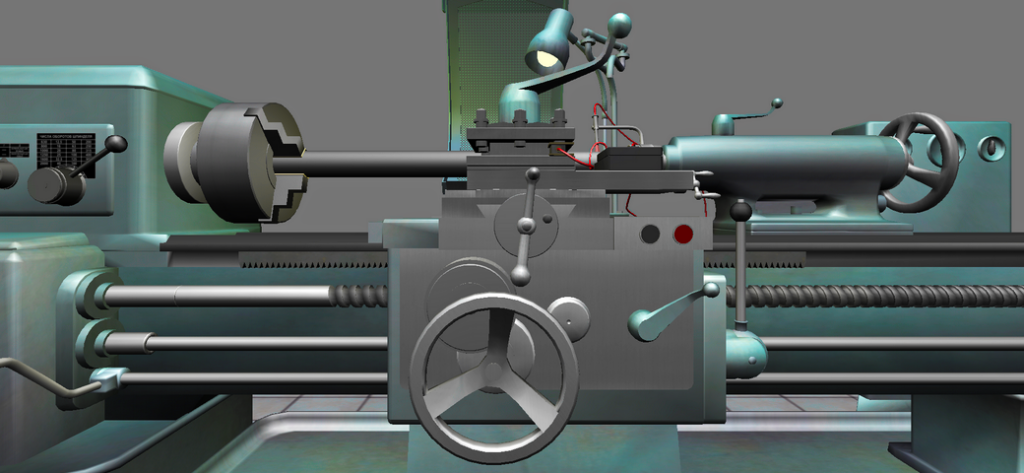

1. Determination of Cutting Forces when Turning on the Lathe Model 1K62

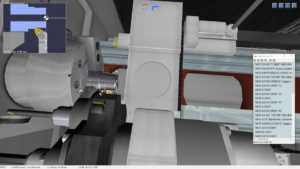

2. Determination of Cutting Temperature when Turning on the Lathe Model 1K62

3. Determination of Wear and Steadfastness of the Cutters when Turning on the Lathe Model 1K62

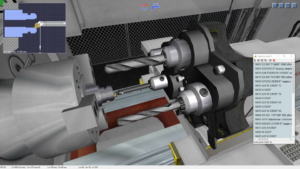

4. The Study of the Geometry of the Working Part of the Turning Cutters

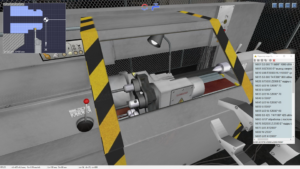

5. Lathe CNC simulator (Control System 2R22)

Target computing device type and platform supported: IBM-compatible personal computer running Microsoft Windows.

The graphics component of the software uses the Microsoft DirectX 9.0.c component base. The graphical user interface of the program is implemented in English.

Minimum System Requirements

- Processor clock speed: at least 1.5 GHz

- RAM: at least 2 GB

- Video memory: at least 256 MB

- Screen resolution: at least 1024x768x32

- DirectX version 9.0.c support

- Standard keyboard and computer mouse with scroll wheel (for PC)

- Audio playback devices (audio speakers or headphones)

Types of Licensing

The Virtual Lab is supplied only for educational organizations with installation on an unlimited number of places (corporate license).

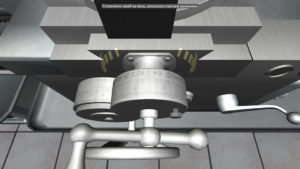

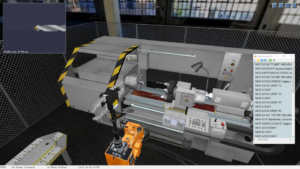

1. Determination of Cutting Forces when Turning on the Lathe Model 1K62

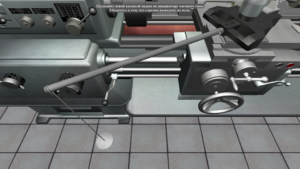

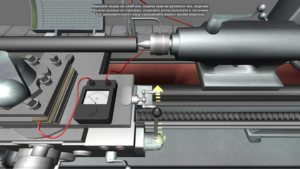

OBJECTIVE: The acquisition skills in determining cutting forces, processing experimental data and obtaining empirical dependencies of cutting forces on cutting conditions on a 1K62 lathe. SUMMARY: The laboratory work is carried out on the basis of the classical lathe model 1K62 with manual control of support. The performance of laboratory work is divided into several stages: calibration of a turning dynamometer; determination of cutting force versus cutting depth; determination of the dependence of the cutting force on the value of the working feed; determination of cutting force versus cutting speed.

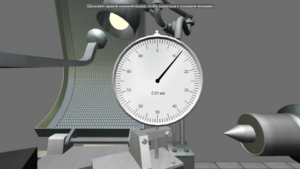

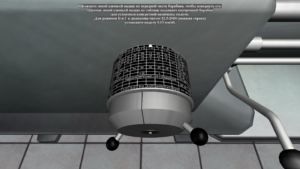

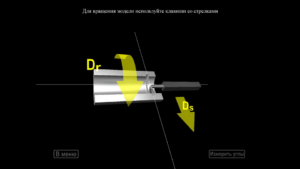

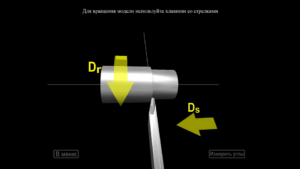

2. Determination of Cutting Temperature when Turning on the Lathe Model 1K62

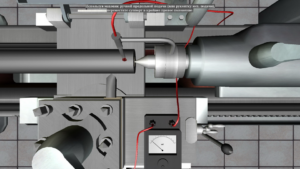

OBJECTIVE: The acquisition of skills to determine the average contact temperature of the cutting area during turning; processing experimental data and obtaining empirical dependences of cutting temperature on cutting conditions on a 1K62 lathe. SUMMARY: The laboratory work is carried out on the basis of the classical lathe model 1K62 with manual control of support. The performance of laboratory work is divided into several stages: determination of cutting temperature from the depth of cutting; determination of dependence of cutting temperature on the value of the working feed; determination of cutting temperature versus cutting speed.

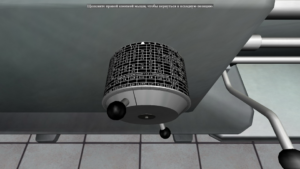

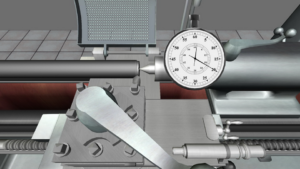

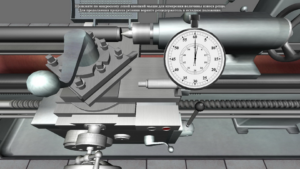

3. Determination of Wear and Steadfastness of the Cutters when Turning on the Lathe Model 1K62

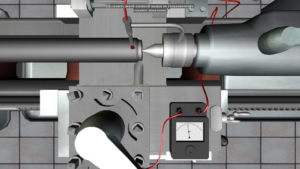

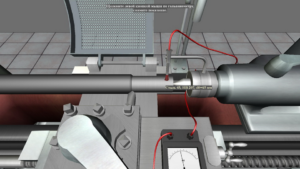

OBJECTIVE: The study the nature of wear of the lathe cutters; determining the allowable amount of wear using the criterion of optimal wear; obtaining the dependence of durability of cutters on cutting speed on a 1K62 lathe. SUMMARY: The laboratory work is carried out on the basis of the classical lathe model 1K62 with manual control of support. The performance of laboratory work is divided into several stages: the definition of the tool wear dependence on the cutting time; definition of dependence «cutting speed – durability of the tool».

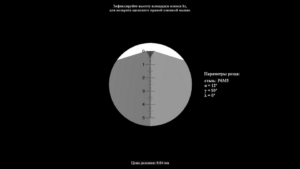

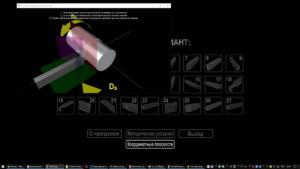

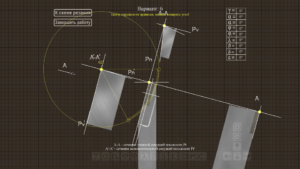

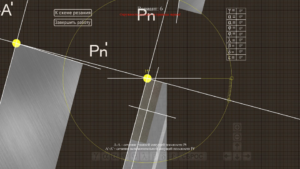

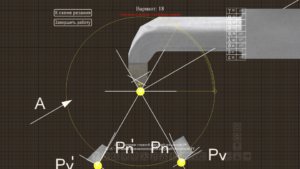

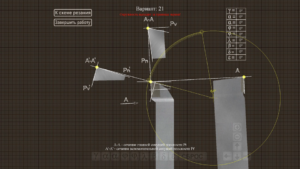

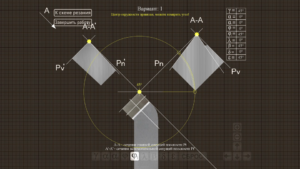

4. The Study of the Geometry of the Working Part of the Turning Cutters

OBJECTIVE: The consolidation the theoretical knowledge of the purpose, application and design of turning tools of general purpose; the familiarization with the methods and means of measuring their geometric parameters. SUMMARY: The 27 variants of the main turning cutters are investigated in the laboratory work. Measurements are made interactively using simple geometric constructions on the computer screen. The scale of the geometric model may changes. During operation, the user makes measurements of the main angles of the working part of the lathe cutters and determines the designation of each angle in the form of an interactive test.

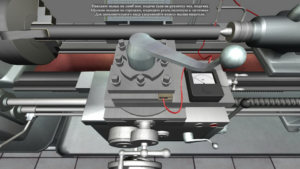

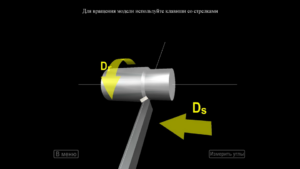

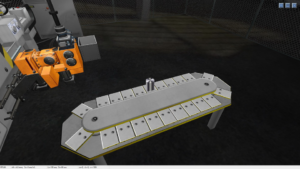

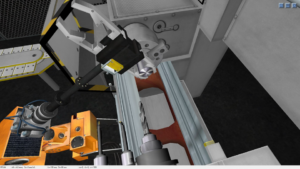

5. Lathe CNC simulator (Control System 2R22)

OBJECTIVE: A visual demonstration and training in programming the processing of metal turning on a robotic technological complex based on a 16K20 turning machine with a 2R22 control system (CNC code standard ISO-7bit). SUMMARY: The simulator is equipped with the code editor of control programs, as well as the menu for selecting the parameters of the working tool and the workpiece. The simulator allows you to create and execute simple control programs for machining parts on a lathe using the international CNC code ISO-7bit.